Lately, the word Industry 4.0 is often echoed by many people. However, until now there are still many people who still do not understand what Industry 4.0 is and how it will contribute to the progress of Indonesia. The term Industry 4.0 was first echoed at the Hannover Fair, April 4-8, 2011. The term is used by the German government to advance industry to the next level, with the help of technology.

Quoting from the Forbes website, the fourth generation industrial revolution can be interpreted as interfering in an intelligent and automated system in the industry. This is driven by data through machine learning and AI technology.

Actually, computer interference is already part of Industry 3.0. At that time, computers were valued as ‘disruptive’, or could be interpreted as something that could create new market opportunities. Once accepted, machine learning and AI are at this stage.

In short, Industry 4.0, industry players let computers connect and communicate with each other to finally make decisions without human involvement. The combination of physical-cyber systems, the Internet of Things (IoT), and the Internet of Systems makes Industry 4.0 possible, and makes smart factories a reality.

In Indonesia, the development of Industry 4.0 was strongly encouraged by the Ministry of Industry. Minister of Industry Airlangga Hartarto said that for Indonesia to compete with other countries in the industry, Indonesia must also follow the trend.

“The Industrial Revolution 4.0 is a transformation effort towards improvement by integrating the online world and production lines in the industry, where all production processes run with the internet as the main support,” Airlangga said.

“We are also studying from other countries that have implemented it, so that we can develop Industry 4.0 with policies based on domestic industrial interests,” he said.

Airlangga also said that a number of national industrial sectors were ready to enter the era of Industry 4.0. Some of them are cement, petrochemical, automotive, and food and beverage industries.

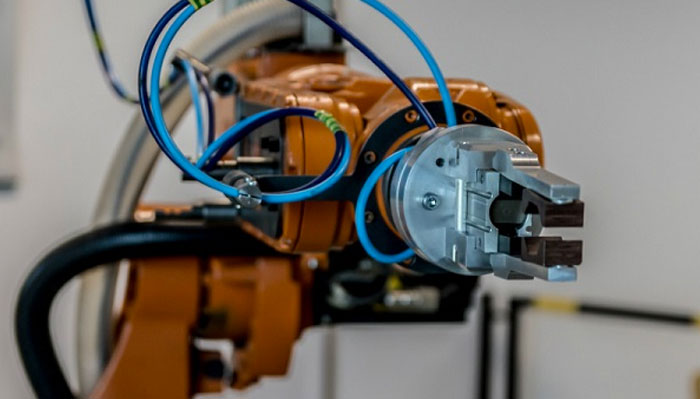

“For example the automotive industry, in their production process, they have used robotic systems and IoT infrastructure,” Airlangga said.

So, what are the driving factors that must be strengthened to welcome Industry 4.0 in Indonesia? According to the Head of the Industrial Research and Development Agency (BPPI) Haris Munandar explained, there were several fields that needed to be prepared.

Some of these include increasing automation, machine-to-machine communication, human-to-machine communication, AI, and developing sustainable technology.

Furthermore, he said that to implement, there are four basic driving factors. First is an increase in data volume, computing power, and connectivity. There should also be an increase in analytical capabilities and business intelligence in this industry.

“New forms of human-machine interaction, such as touch interfaces and augmented-reality systems, are also important. Not to forget, the development of digital instruction transfer into physical forms, such as robotics and 3D printing, “he stressed.

The Ministry of Industry has also begun to provide impetus to prepare whatever is needed by industry players. They have done several things, such as providing incentives to labor-intensive businesses in the form of industrial infrastructure, collaborating with the Ministry of Communication and Information Technology in optimizing bandwidth, and providing the National Industrial Information System (SIINAS) that facilitates data integration to build the electronic industry.

Not to forget, the preparation of industrial human resources through vocational education that leads to high skills and improving the skills of dominant industry low / middle to high skill levels has also been carried out.

So, which companies have implemented Industry 4.0 in Indonesia? Apparently, one of the factories that has adopted directly is a German electric appliance factory in Indonesia, namely PT Schneider Electric Manufacturing Batam (SEMB).

In the official website of the Ministry of Industry, the two parties collaborated on the application of Virtual Reality technology to control the condition of the machine. This collaboration was carried out when Airlangga visited the factory on November 16, 2018 ago.

On the other hand, Telkomsel as one of the Industry 4.0 enablers is also ready to support the implementation of this in Indonesia. They will provide the IoT system, through the Telkomsel Innovation Center (TINC) program.

“The TINC program summarizes various activities in shaping the Indonesian IoT ecosystem, in the form of providing IoT laboratories, mentoring and bootcamp programs with expertise in the IoT field, as well as networking access for startups, developers, and system integrators with related industry players,” said Denny Abidin, General Manager of External Corporate Communications Telkomsel.

Telkomsel has also developed cross-industry IoT services. One example of the fields that have collaborated with them is in the banking sector. Telkomsel is a partner provider of IoT connectivity and IoT platforms.

Likewise in the transportation, automotive and logistics sectors. They have provided a total IoT solution. Not to forget, they are also preparing themselves to help industries engaged in agriculture, aquaculture, environmental and monitoring. This red-template company has become a liaison, incubator, and accelerator.

One more thing that must be prepared by the Government of Indonesia to welcome Industry 4.0. One of them is through the preparation of the presence of the fifth generation network or better known as the 5G network.

The Minister of Communication and Information, Rudiantara also on various occasions confirmed that the 5G network was prioritized for industrial needs. Not for individual users only.

“The application of 5G technology was originally for industry, machine to machine. How robots can replace forklift vehicles in lifting goods, so the application for these things is not an application for individuals, “said Rudiantara.

Until now, there have been several operators who have tried the 5G network in Indonesia. Call it Telkomsel, which had conducted a trial at the 2018 Asian Games, followed by XL by conducting a network test in Kota Tua in the middle of last year.

On the other hand, Indosat has demonstrated how the 5G network can be applied in Industry 4.0. In their 51st birthday on September 21 last year, they have shown how they can help the industry.

At that time, the Minister of Communication and Information Rudiantara tried to use an AR headset connected to the 5G network. By using this network technology, he can control equipment in the virtual world without any network lag interference.

“Our industry today, in digital, is amazingly changing fast and indeed the dynamics are extraordinary. Although not yet officially marketed, currently 5G technology is a trend that continues to be pursued so that it can be implemented by all telecommunications operators in the world. The adoption of 5G technology is done to improve customer and industry experience, “he said.

Source: kominfo.go.id